TECHNOCRATS PLASMA SYSTEMS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TECHNOCRATS PLASMA SYSTEMS P.LTD.

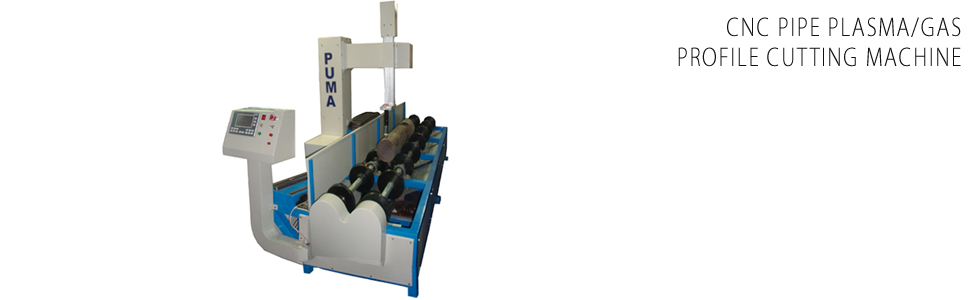

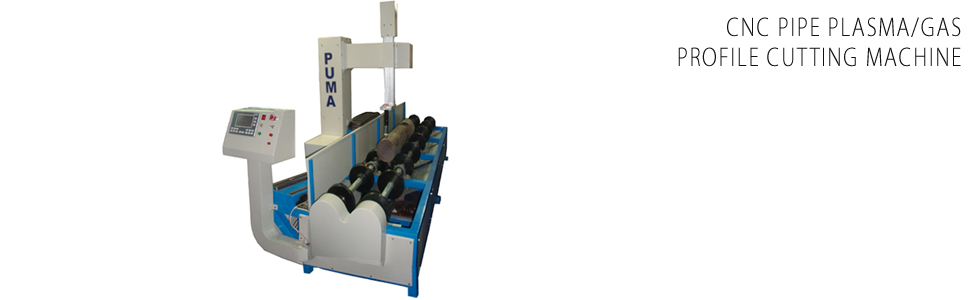

Pipe Profile Cutting Machines

The CNC Controlled Pipe Profile Cutting Machine provides wide working range from diameters 30mm to 1500mm and pipe lengths from 100mm to 12000mm using oxy fuel or plasma.

Different Models such as "PUMA-RX" & "PUMA-BX" covers almost entire spectrum of requirements, Puma is a simple 3-Axis Machine with Disc supports for pipe. Minimum & Maximum dia. Depends upon the size and spacing of disc on shaft. Bevel Cutting at ends are possible by adjusting the angle of torch manually. Puma-BX is 5 axis Machine which meets almost all known requirements for pipe profile cutting. Auto Cad Drawing are imported into the controller for further processing. Once the command is given cutting is done automatically on both the ends without any interference. The most important feature of this machine is it is very simple to learn and operate. Any Computer Operator can be trained within 2 hours.

By simply clicking on a joint one can select the job for cutting. Intelligent Fume Extraction System and Air Conditioned Control Cabin is supplied on request which makes it convenient for the users to work in deserts and hot places.

The CNC based pipe profile cutting machine PUMA, is a unique innovative product from Technocrats Plasma Systems. It can be used for all profile cutting needs on smaller as well as bigger size pipes. It is available in different size variants. Puma can either be Chuck driven or Conveyer driven. The machine uses state-of-the art technology in cutting (plasma or oxyfuel), electronics and software. It delivers superb cut quality and productivity at a much lower overall cost. It eliminates time consuming processes of forming templates and manual cutting and subsequent grinding. It produces smooth cut profiles as per drawings and all that in a fraction of the time involved in manual processes. All these qualities put together, Puma profile cutting equipments provide an excellent ROI.

Boon for round pipe/rectangular pipe profile cutting applications. Enhances productivity several folds. Can cut profiles on circular and rectangular sections. AutoCAD drawings of the pipe are unfolded in our software and converted into codes by nesting software. Option for plasma or oxy fuel cutting. Infrastructure projects, power projects, cement plant projects, pipe line projects, material handling projects find this product most productive for their projects. Beveling attachment produces bevel cut required for welding on profiles.

Features

Models

Industries

Spares & Consumables

Downloads

Photo & Video

Get Quote

Share Review

Special Features:

• Two Variants - chuk -held/Resting on conveyor.

• Profiles in accordance with AWS and API Standards (Mitre, Saddle, hole) or any other profile extracted from drawings.

• Suitable for Plasma/Oxyfuel.

• Precision Guide ways.

• Digital AC Servo drives and motors for high speed, superb control, high precision and high repeatability.

• Low backlash (<7 arcmin) heavy-duty gearboxes for smooth motion.

• Cable drag chains for hoses and cables.

• Positioning Accuracy: +/- 0.5 mm, Repeatability: +/- 0.5 mm

• Drive rack mounted directly on surface with pprecision guide ways for precise alignment.

• Drive Speed upto 15m/min.

• Provision for beveling.

• Software for unfolding and DNC software built-in.

• Upto six controlled Axes with precision machined Rack & Pinion Drives / Ball screw mechanisms.

• Working Length – Flexible (1m to 20m).

• Chuck as well as disc support.

• 3-axis & 5- axis models.

• Possible to cut bevel on all profiles.

• Accepts AUTOCAD drawings (.dwg, .dxf etc).

• Possible to pierce up to 50mm thick metals.

• Longitudinal Conveying.

• Versatile- Can cut any profile.

• Numerous Interface Options.

• BEVEL unit can be added.

• Bluetooth Enabled.

• Provision for scissor supports (chuck held type).

• Provision for longitudinal transfer of pipe (Conveyor Type).

• Torch Height Control (Optional).

• Plasma & Oxy-fuel cutting.

• Remote diagnostics.

• Super cut quality.

• Maintenance free.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.